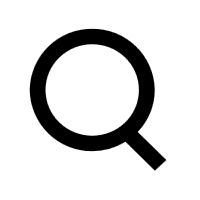

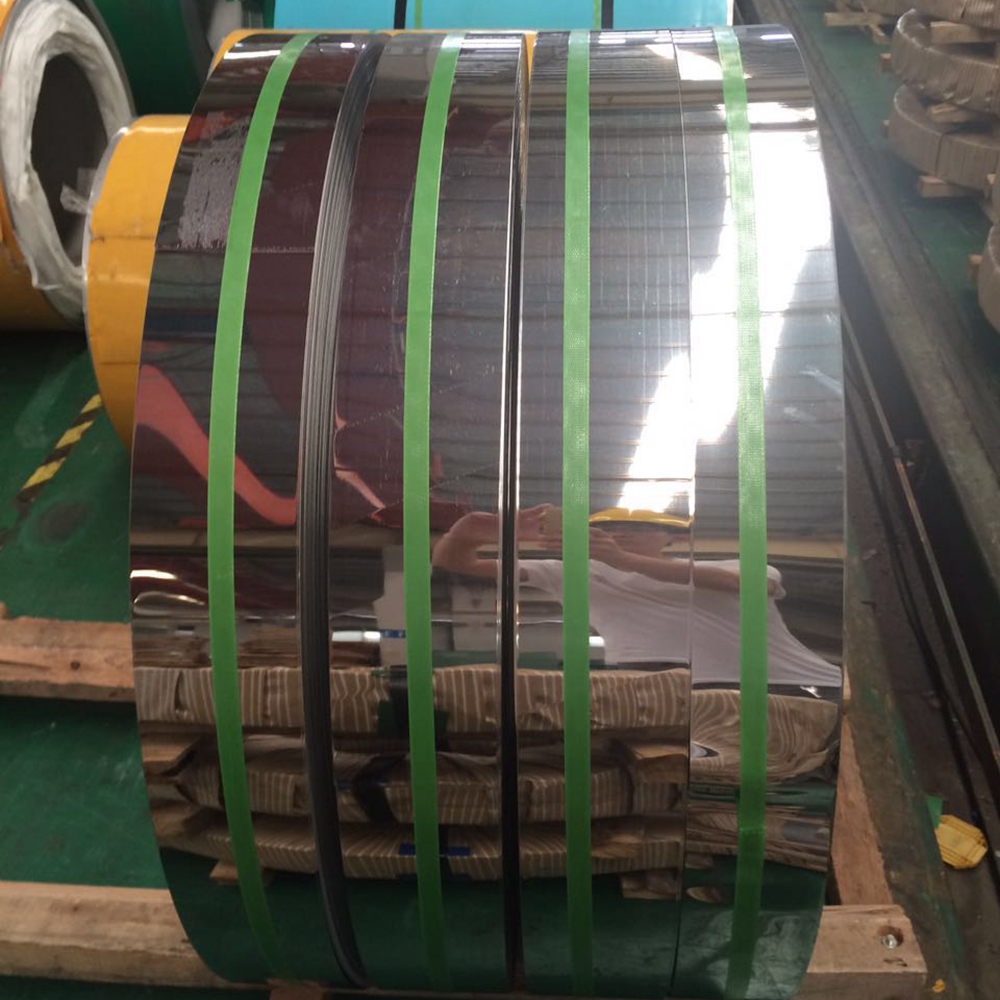

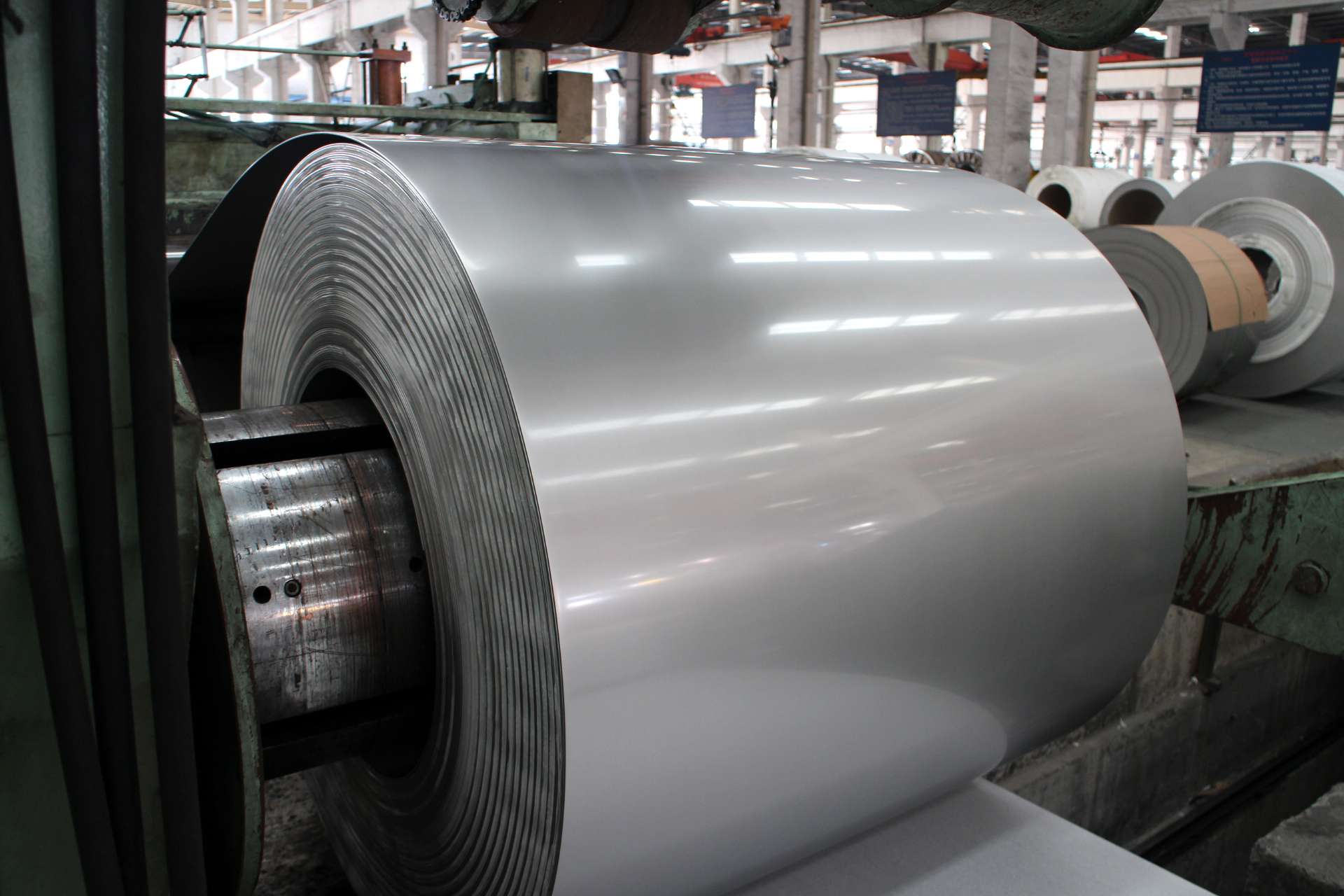

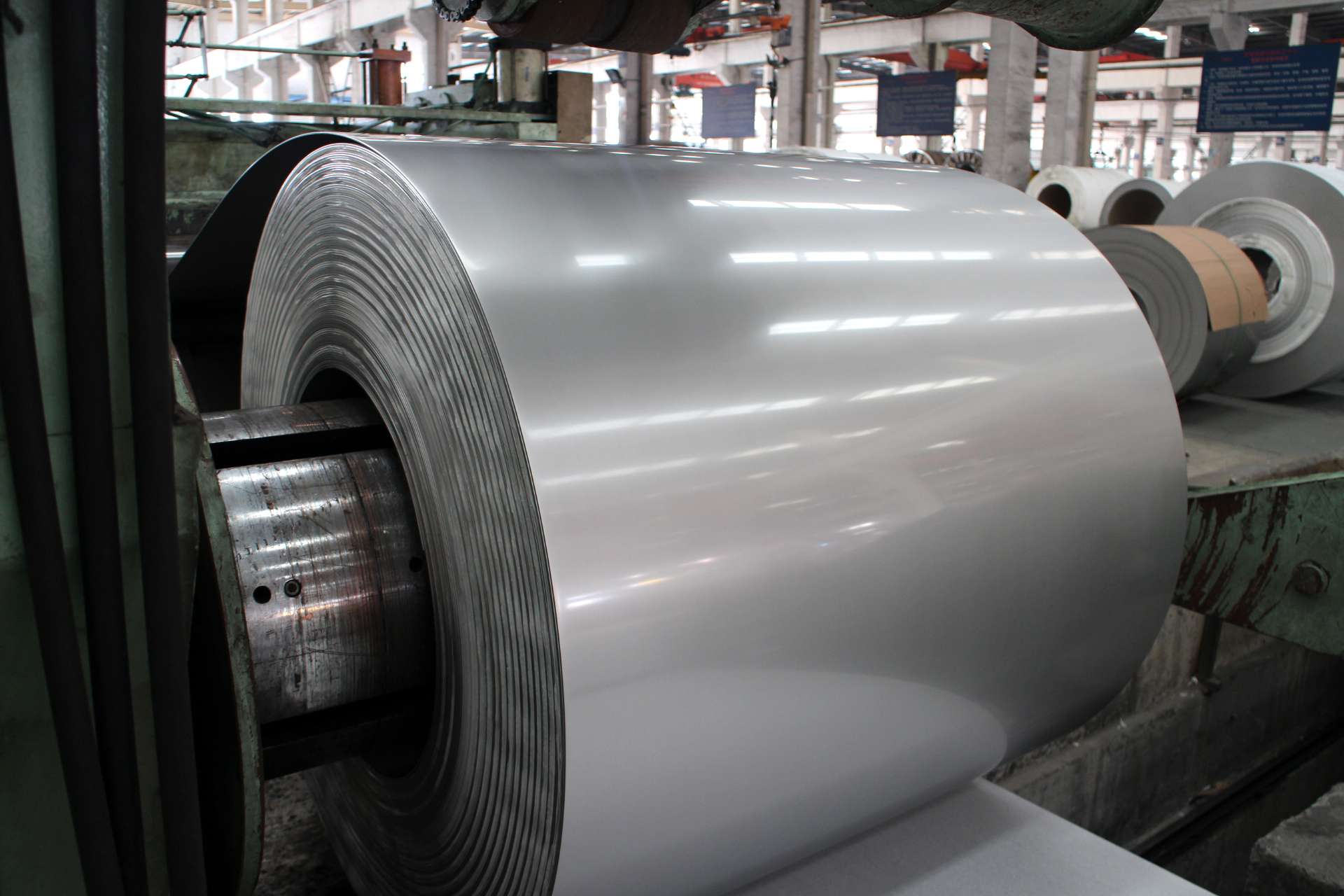

316 316L stainless steel coil

The maximum carbon content of 316L stainless steel is 0.03, which can be used for applications where annealing is not possible after welding and maximum corrosion resistance is required. Corrosion resistance The corrosion resistance of 304 stainless steel is better than that of 304 stainless steel. It has good corrosion resistance in pulp and paper making process. Moreover, 316 stainless steel is also resistant to marine and corrosive industrial atmospheric erosion.

- Previous:321 stainless steel coil

- Next:201 stainless steel coil

Links:

Trueland

Language

Language